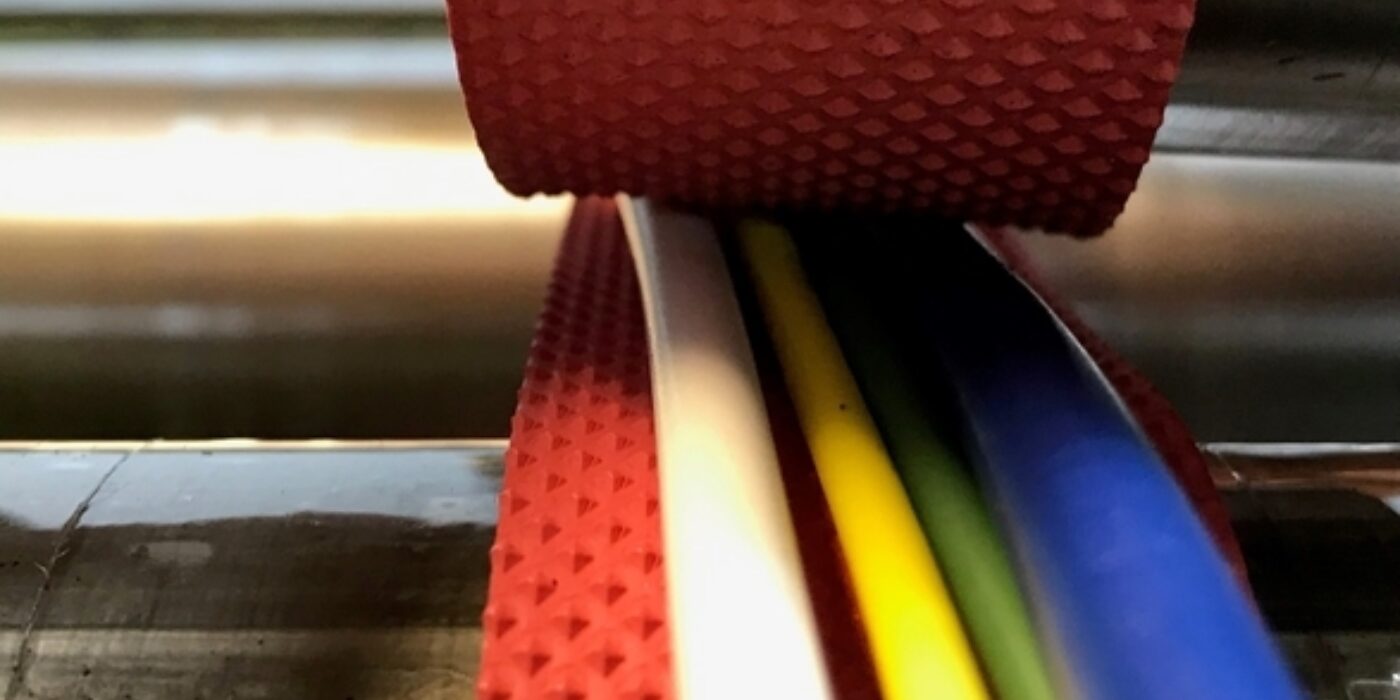

ERG 008 - Engineering wire feeder belt with rhombic structure

Overview Engineering Reports Graf Technical supportInitial situation

In order to be able to develop a cost-optimized and flexible wire feeder belt for a wide variety of electro cable diameters, an engineering company commissioned by the system manufacturer contacted the Engineering department of Dipl. Ing. Werner Graf AG. They wanted to discuss material properties, manufacturing possibilities and manufacturing processes already at the planning process.

Task

A high flexible haul-off belt with extremely high friction coefficient, suitable for cable cross-sections between 1.5 mm2 up to max. 18.0 mm2 should be developed. The haul-off must enable fixed axes and still ensure functionality for all cross-sections.

Solution

A conventional haul-off belt is usually designed and optimized based on the diameter, cross sections and the necessary withdrawal force. The variable component "cross section" already requires the highest coefficient of friction in the processing material, the different cross sections the lowest possible shore hardness. The rubber quality must support the required flexibility, the design of the surface as few as possible mechanical processing steps bring with it.

The result: a one step cured rhombic surface structure that preserves the high coefficient of friction of the material, supports flexibility and eliminates the needs for mechanical reworking.