ERG 009 - Technical engineering of a friction clutch

Overview Engineering Reports Graf Technical supportInitial situation

The medium-sized company has been a leading manufacturer of clothing and cutting machines for more than 30 years and develops patented as well as innovative automation solutions for cable processing machines. For many years, the customer has relied on the valuable cooperation with the Dipl. Ing. Werner Graf AG. In the buisness of endless coating, Swiss precision as well as variety are particularly valued.

Task

During the annual meeting with the technical manager, new production possibilities are discussed due to our constantly updated and modernized production plant and new applications of our products are presented. The geometric design of our classic friction feeder allows a limitless variety in terms of application and technical engineering of new technologies. In the development, solutions for a mechanical friction clutch are sought and has been assigned to the engineering team of Dipl. Ing. Werner Graf AG.

Solution

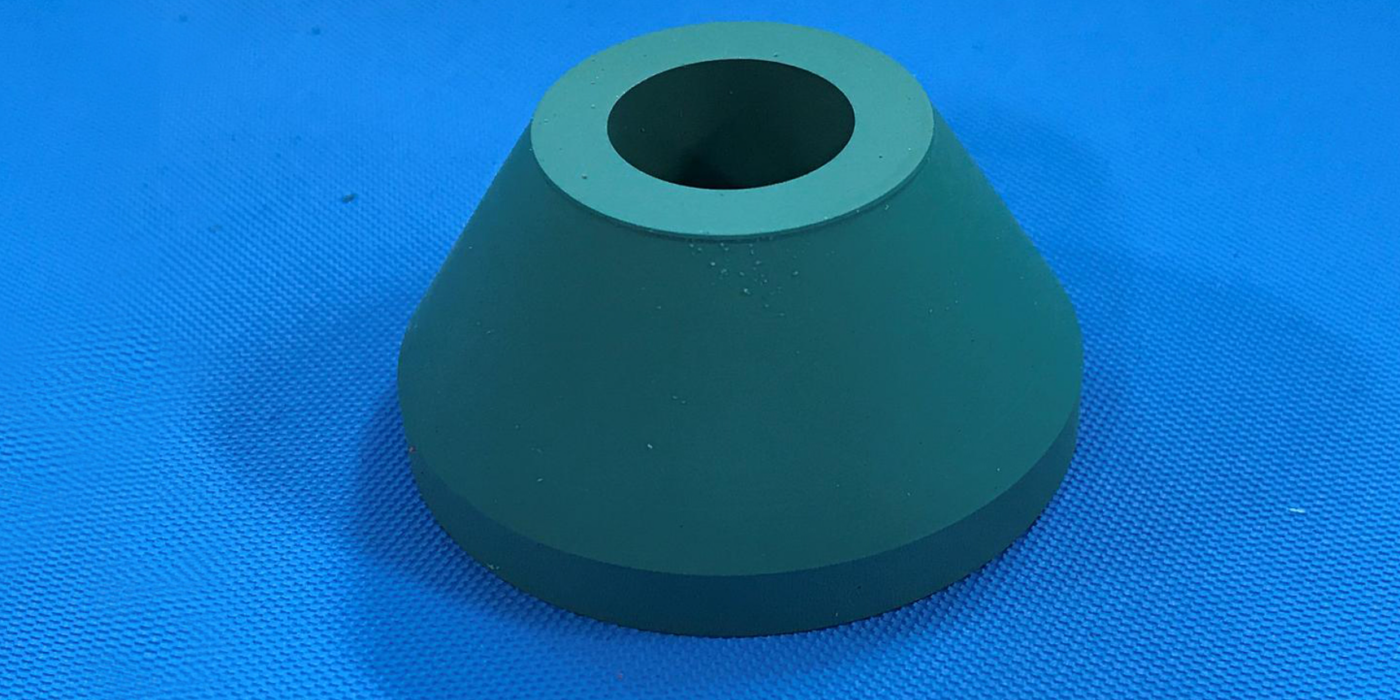

In the customer-specific system there are several carriages which must be driven and stopped in different positions in the system. The FDA-compliant drive and driven roller is intended to lock or slow down a conical cone by means of frictional engagement. In order to be able to find a pragmatic and economic solution, the required parameters were exchanged and coordinated in the lively exchange between customer construction and technology of Dipl. Ing. Werner Graf AG.

The result: a tailor-made friction lining developed in the joint ideas workshop.